18098 CORPORAL WILLIAM JAMES HUNT

ROYAL ENGINEERS

by

Lieutenant Colonel Edward De Santis

© 2019. All rights reserved.

Pre-Service Data and Physical Description

William James Hunt was born in Charles Parish near the town of Plymouth in the County of Devonshire in January of 1865. He was the son of William and Mary Anne Hunt of 3, Higher Street, Plymouth. When William entered the Army in 1883, his mother was residing in Plymouth and his father was in the United States (Washington).

At the time of his enlistment in the Army, Hunt was 18 years and 7 months old. He was 5 feet 4-1/2 inches tall and weighed 123 pounds. His chest measurement was 34-1/2 inches. Hunt had a fresh complexion, blue eyes, and dark brown hair. His distinguishing marks included a large mole on his right shoulder, small round tattoo marks on the back of his left hand, and a scar on his right groin. He was a sawyer by trade and a member of the Church of England. Hunt was unmarried and had no prior naval or military service.

Enlistment

Hunt joined the Royal Engineers at Plymouth on the 14th of August 1883. He was given notice of his enlistment by Orderly Sergeant A. Gwin of the Devonshire Regiment and attested for a short service enlistment of 12 years.

Hunt's enlistment was witnessed by Sergeant G. Moseley of the Devonshire Regiment and was certified by a magistrate in Plymouth on the 14th of August 1883. On this same date he was declared to be medically fit for military service by Surgeon Major R. Turner at Devonport. Major Alfred B. Letts of the 3rd Battalion, the Devonshire Regiment declared that Hunt's attestation was correct and proper and certified that credit for his recruitment was due Superintending Clerk D. Bingham of the Royal Engineers.

On the 15th of August 1883 at Exeter, Hunt's attestation was certified by the Approving Field Officer, the Commanding Officer of the Regimental District.

Record of Service

William James Hunt was given the Regimental Number 18098 and the rank of Sapper, and was trained and assigned to duties as an engine driver with a Submarine Mining unit. His home and overseas service included the following stations and periods:

Country From To

England, Ireland and Bermuda 14 August 1883 19 October 1885

Scotland 20 October 1885 10 November 1885

Halifax, N.S., Canada 11 November 1885 15 October 1888

Bermuda 16 October 1888 15 January 1894

England (Plymouth) 16 January 1894 15 November 1898

St. Lucia (West Indies) 16 November 1898 13 January 1903

Scotland (Greenock) 14 January 1903 13 August 1904

After an initial period of training at the School of Military Engineering at Chatham in Kent, Sapper Hunt was assigned to the 2nd Section, 27th Submarine Mining Company. This company was formed at Chatham on the 1st of April 1882. The company deployed on training exercises at Sheerness in 1883. The 2nd Section subsequently deployed to Cork, Greenock, and Gosport in May, October and November of 1884, respectively.

In April of 1885 the 2nd Section returned to Cork and subsequently rejoined the company headquarters at Devonport in August of 1885. Hunt deployed with the 2nd Section to Bermuda in October of 1885 and after a stay of less than a month he sailed for Halifax, Nova Scotia. In October of 1888 the 27th Company was divided into two companies; the 40th which remained at Halifax, and the 27th which returned, to Bermuda. Hunt remained with the latter.

In January of 1894 Hunt returned home and was stationed on submarine mining duties at Plymouth. The Central Company (formerly the 30th Company) for the Submarine Mining School was stationed at Plymouth at this time. He served there until the 15th of November 1898 when he was assigned to St. Lucia, a British island possession in me West Indies.

On the 14th of January 1903 Hunt returned to Great Britain and was assigned to No. 3 (Clyde) Section of the Coast Battalion. No. 3 Section was at that time stationed in Greenock on the Firth of Clyde and was commanded by Major T. Davis, R.E.

During Hunt's period of military service the British Army was involved in major wars in Egypt and South Africa, as well as numerous minor campaigns on the northwest frontier of India. Many Royal Engineers units were involved in active service during this period. Hunt's military career was one of peace-time soldiering. As a result, Corporal Hunt was entitled to no campaign medals or awards for gallantry or meritorious service. He did, however, do a considerable bit a traveling while in the Army. During his 21 years of service Hunt served at 10 different duty stations, 7 in the United Kingdom and 3 abroad.

Promotions, Awards, and Education

Hunt served in the rank of Sapper for just under four years when he was granted Good Conduct Pay at the rate of 1 penny (l.d) per day on the 27th of April 1887 while serving in Nova Scotia, Canada. During this period of service in Canada he also received a Third Class Certificate of Education on the 27th of March 1886. On the 14th of August 1889, the anniversary of his sixth year of service, Sapper Hunt was granted Good Conduct Pay at 2.d per diem while serving in Bermuda. On the 20th of July 1891 he extended his service to complete 12 years with the Colours.

Sapper Hunt re-engaged to complete 21 years of service on the 26th of January 1895 with the authorization of the Commander Royal Engineers at Plymouth. He was granted Good Conduct pay at the rate of3.d per day on the 14th of August 1895 while he was still serving at Plymouth and was appointed Lance Corporal on the 31st of October 1895. He was promoted to 2nd Corporal on the 1st of December 1897.

Hunt's final promotion to Corporal came on the 1st of September 1900 while he was serving at St. Lucia. He returned to England on the 14th of January 1903 and was discharged at Greenock on the 13th of August 1904 on termination of his second period of limited engagement in accordance with paragraph 1805, Section XXI, King's Regulations dated 1899.

Personal

Data

William James Hunt married Lavinia M. Fraser

(without leave) at Halifax, Nova Scotia, Canada on the 29th of September 1887.

The Hunts had no children during Corporal Hunt's time in service.

Discharge

Corporal Hunt was discharged at Greenock on the 13th of August 1904 upon completion of exactly 21 years of service. His discharge was confirmed on this date at Edinburgh by the Commander Royal Engineers, Scottish District. His conduct while serving was classified as "Exemplary" and his special qualifications for employment in civil life were listed as "Engine Driver" and his abilities rated as "Superior." Hunt was awarded the Long Service and Good Conduct Medal in accordance with Army Order 10c of 1903.

At the time of his discharge Hunt was 39 years and 7 months old, 5 feet 6 inches tall, with a 38 inch chest measurement. His complexion was still described as fresh and his hair dark brown, but slightly grey. He had the same distinguishing marks upon discharge from the service as he did when he enlisted.

Hunt's intended place of residence upon discharge was 2, Beaumont Avenue in Plymouth.

REFERENCES

1) WO 97/5187

Public Record Office

Army Form B.265. Short Service Attestation.

Description on Enlistment

Certificate of Primary Medical Examination

Certificate of Final Medical Examination

Certificate of Primary Military Examination

Certificate of Approving Field Officer

Statement of Services

Military History Sheet

Army Form B.268. Proceedings on Discharge.

2) BAKER BROWN, W. History of Submarine Mining in the British Army. W.J. Mackay & Co., Ltd, Chatham, 1910.

ADDENDUM 1.

The following comments regarding the death of William

James Hunt are from the R.E. Old Comrade's Association News from the Branches

(Plymouth Branch). These comments

were published on page 162 of "The Sapper" magazine of May 1947.

"During the past month we

have lost three Old Comrades, who all passed away suddenly."

". . . our oldest local Old Comrade, Cpl. W.J. Hunt (Winkle Diver), at the

grand old age of 82. The following old comrades attended the funeral as pall

bearers, W. Axon, L. Morrish. T. Harris, E. Baker, W. Holman, and R.

Collins."

From this notice the following information can be added to the record of Hunt's life:

1. Corporal Hunt appears to have remained in the Plymouth area where he took up residence upon his discharge from the Army in 1904.

2. Based on the wording of the death notice, it appears that Corporal Hunt died in April of 1947.

3. Two of the pall bearers have been identified. W. Axon served in the Royal Engineers (Army Number 1854398), probably from the time of the Great War. He died on the 24th of June 1963. 1866401 Sapper W. Holman also served in the Royal Engineers during the reign of King George V.

NOTE: The source of these data regarding Axon and Holman are from

the Royal Engineers Research Service data base created and maintained by the

author.

4. The term "Winkle Diver" used in the death notice is a mystery. The "Chambers English Dictionary" (Cambridge, 1988) gives two definitions for the word winkle.

a. A periwinkle - a creeping evergreen plant growing in woods.

b. The penis (slang):

Unless the usage of the word winkle was much different

in 1947 than it was in 1988,

it is hard to see how the word applies to Corporal Hunt's diving duties.

ADDENDUM

NO. 2

SUBMARINE

MINERS AND THEIR WORK

(From "REGIMENT" Magazine, Issue Thirteen, April/May 1996, The Corps

of Royal Engineers)

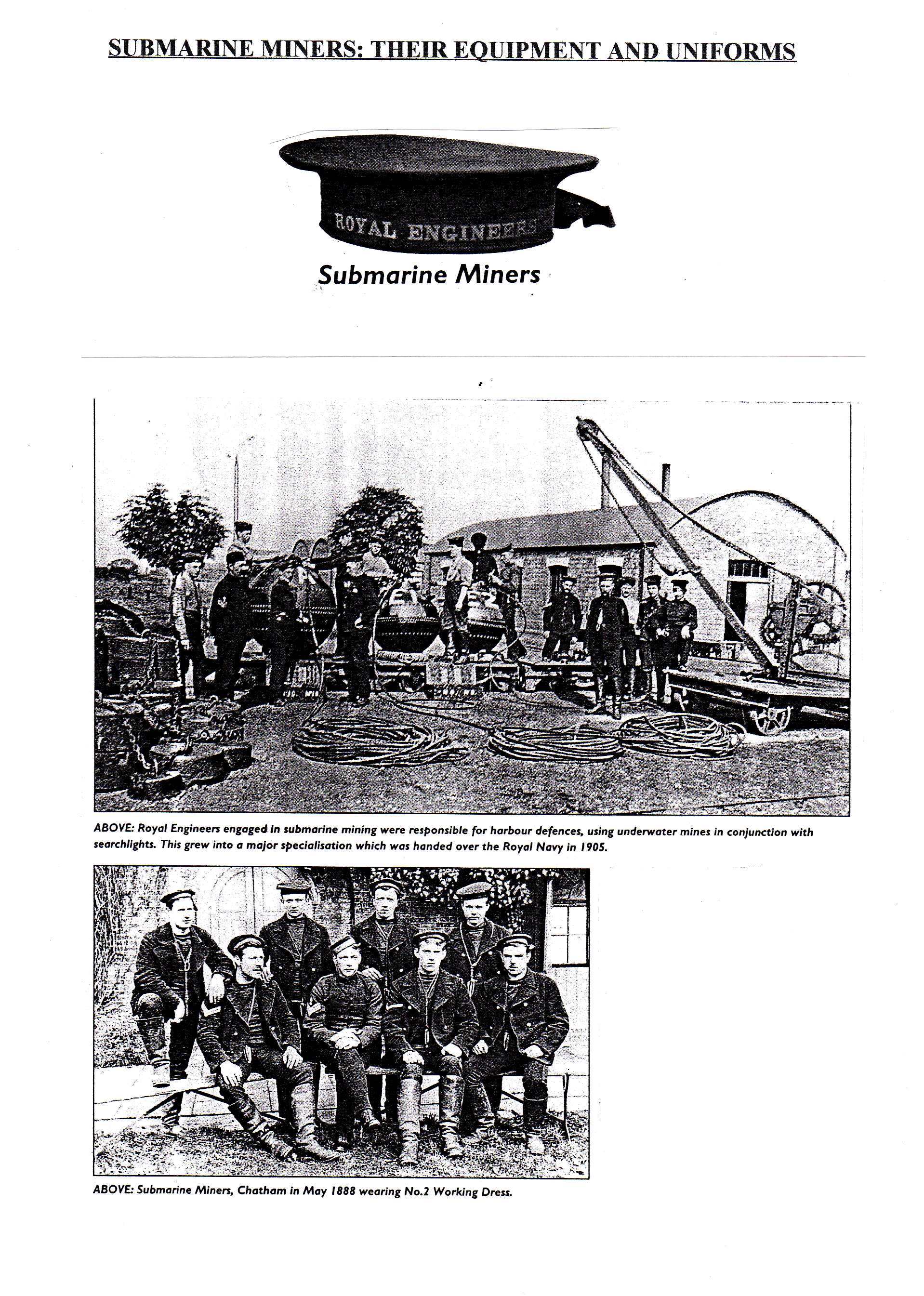

The Submarine Mining Service, which provided an efficient shore based defence for British naval bases between 1871 and 1905, was a specialist wing of the Royal Engineers.

During the 1860s underwater mines were developed as reliable weapons for coastal defence. On the recommendation of General Sir John F. Burgoyne, R.E., their manning and control fell to Royal Engineers units operating alongside Coastal Artillery. The Corps' experiments with the new electricity and underwater wreck clearance provided valuable skills, and the first Royal Engineers Submarine Mining Company was formed in 1871.

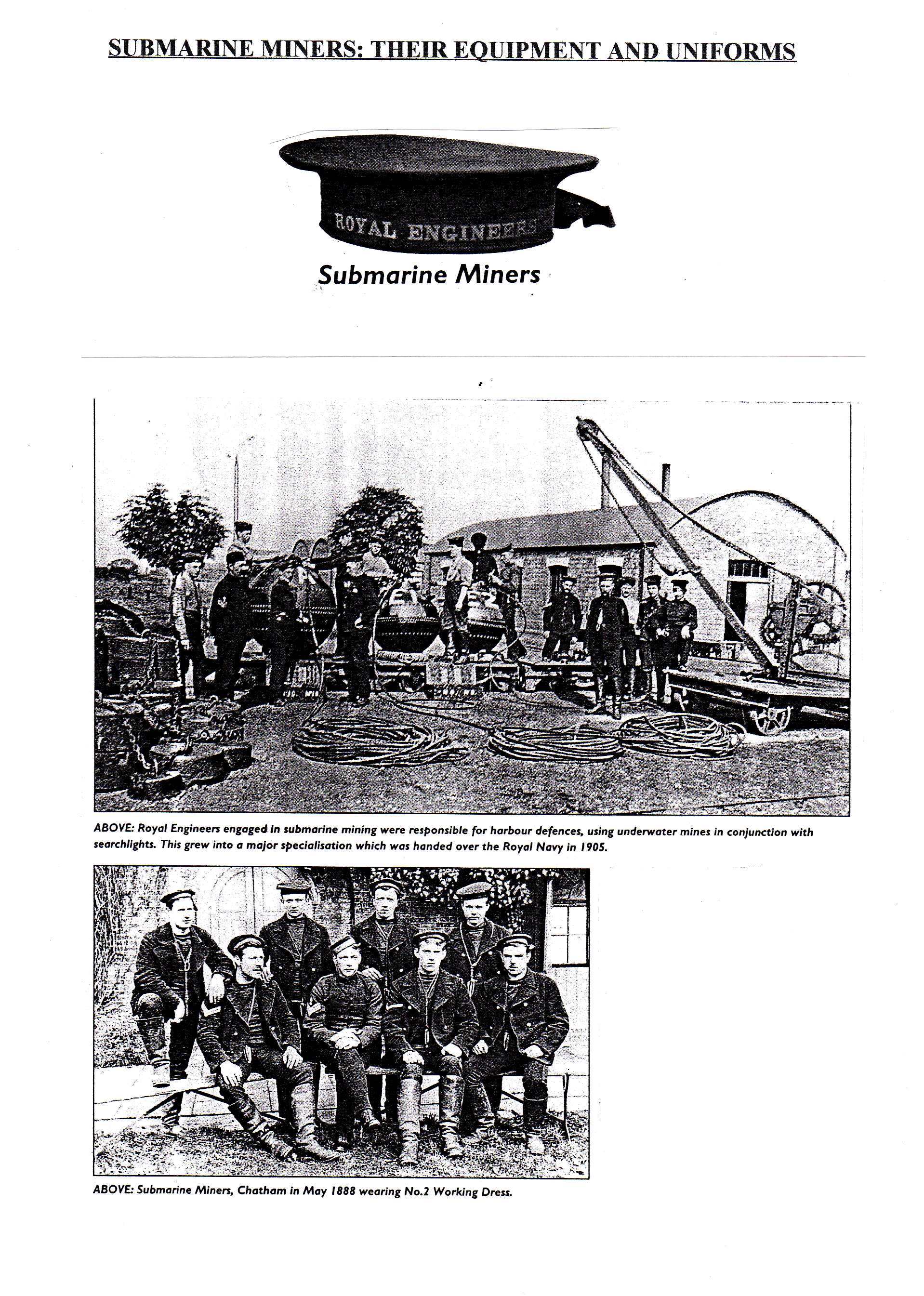

As well as being physically fit to move the heavy mines around, such soldiers were also selected for their brains and scientific knowledge. After initial training and such mundane tasks as coiling the electrical cables used to connect the mine to the shore, the men moved on to be instructed as divers, electricians, instrument repairers, or engine drivers. Working dress included a pea jacket, sailor's cap and "sou'westers" for rough weather at sea.

The Submarine Mining Service expanded rapidly - there were four companies by 1882 and nine by 1886, with detachments throughout the British Empire, plus a number of Volunteer Submarine Mining Corps.

By 1904 it was decided to hand responsibility for coastal defence back to the Royal Navy and the following year the Navy took over coastal forts, mines and mine laying craft, but not the Coast Defence Electric Lights, which later passed to the Royal Artillery.

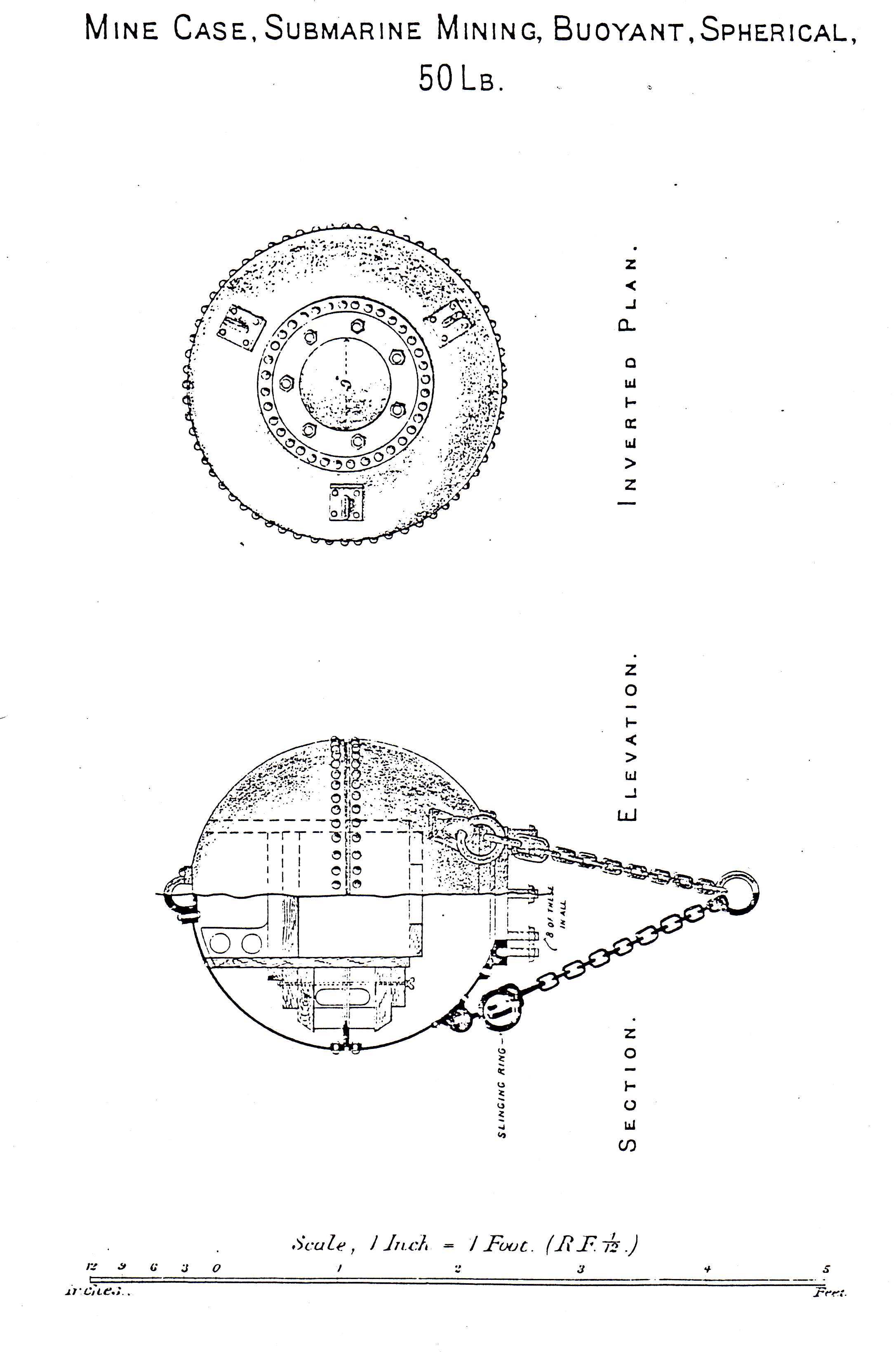

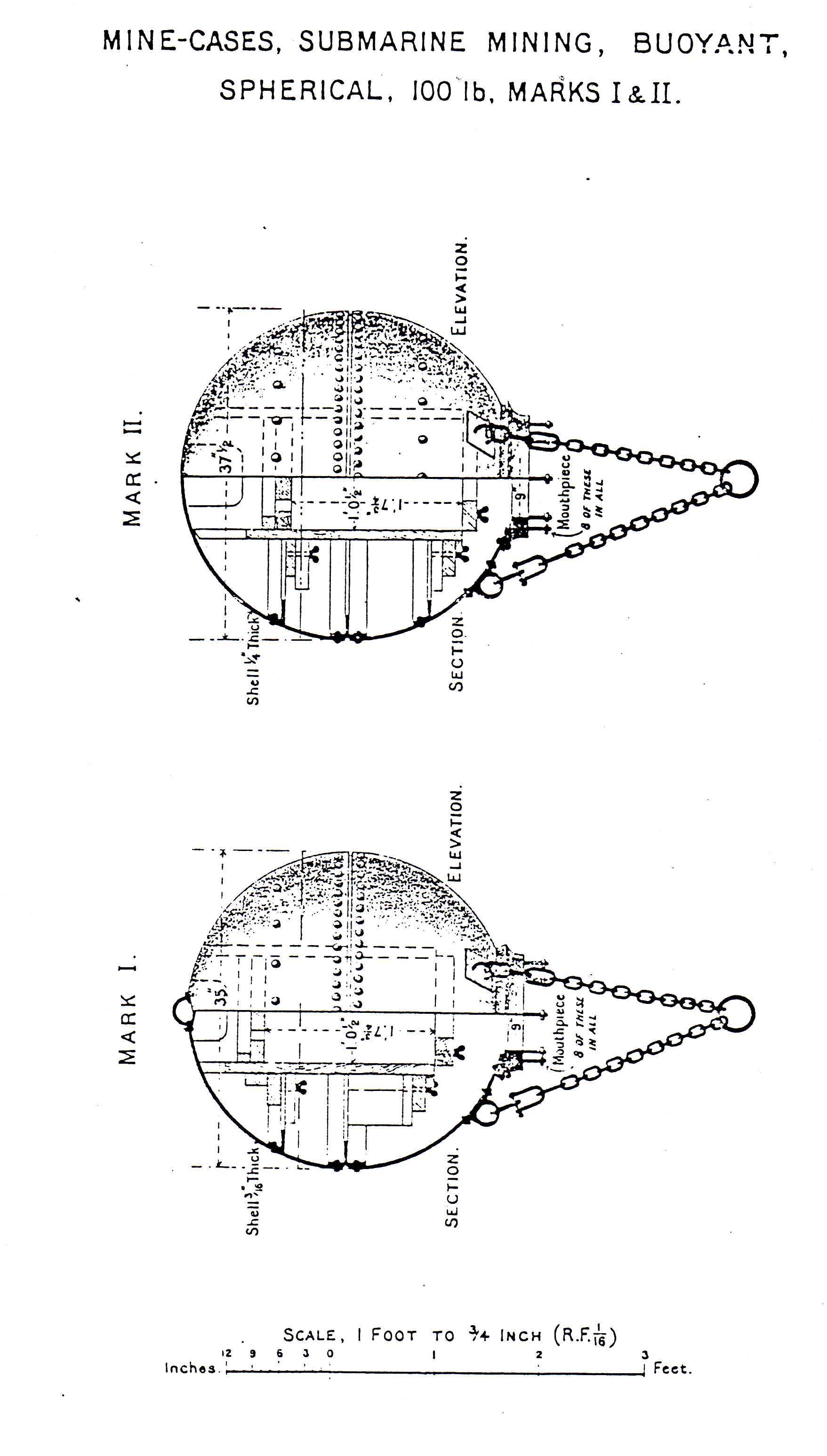

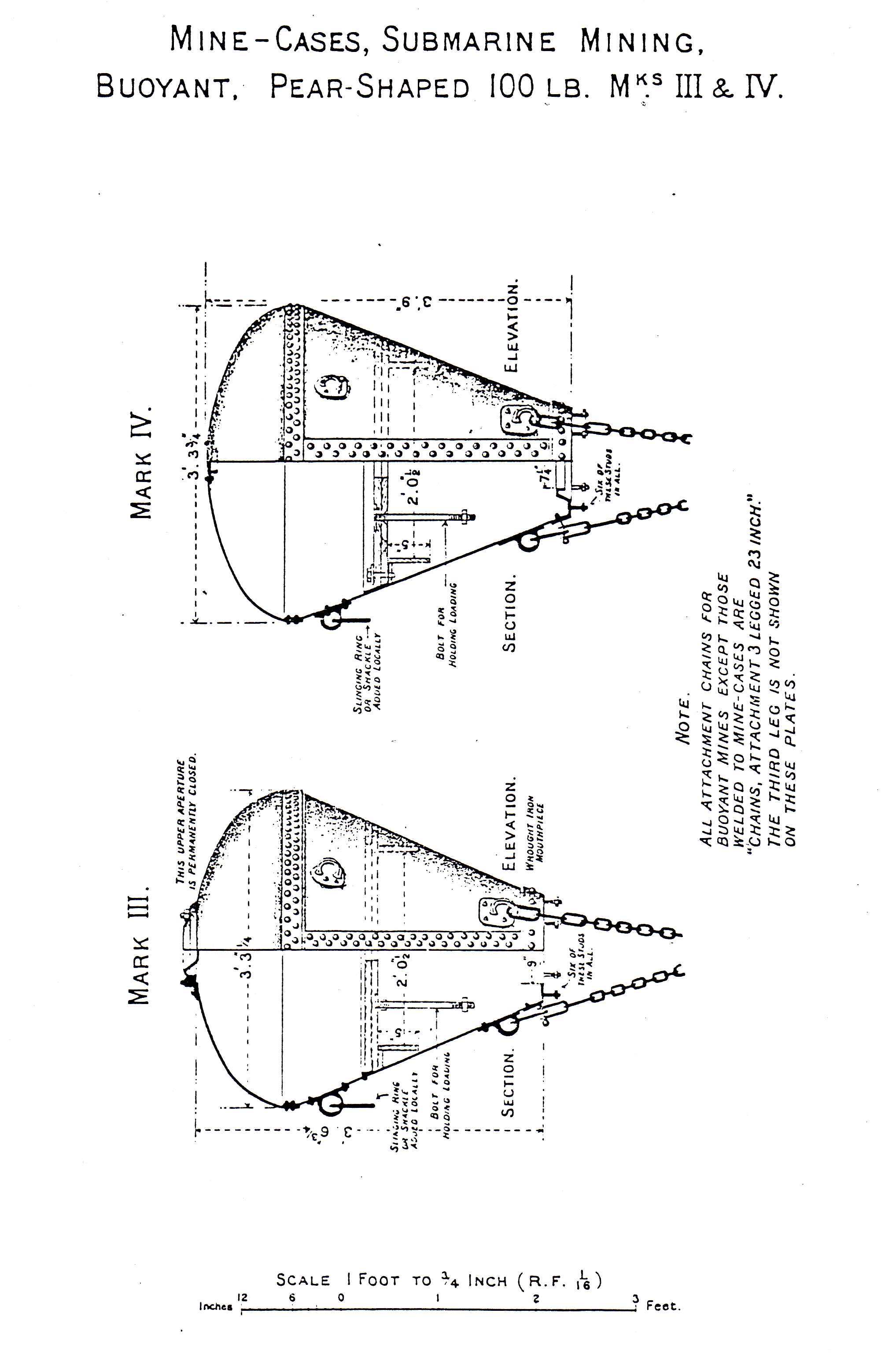

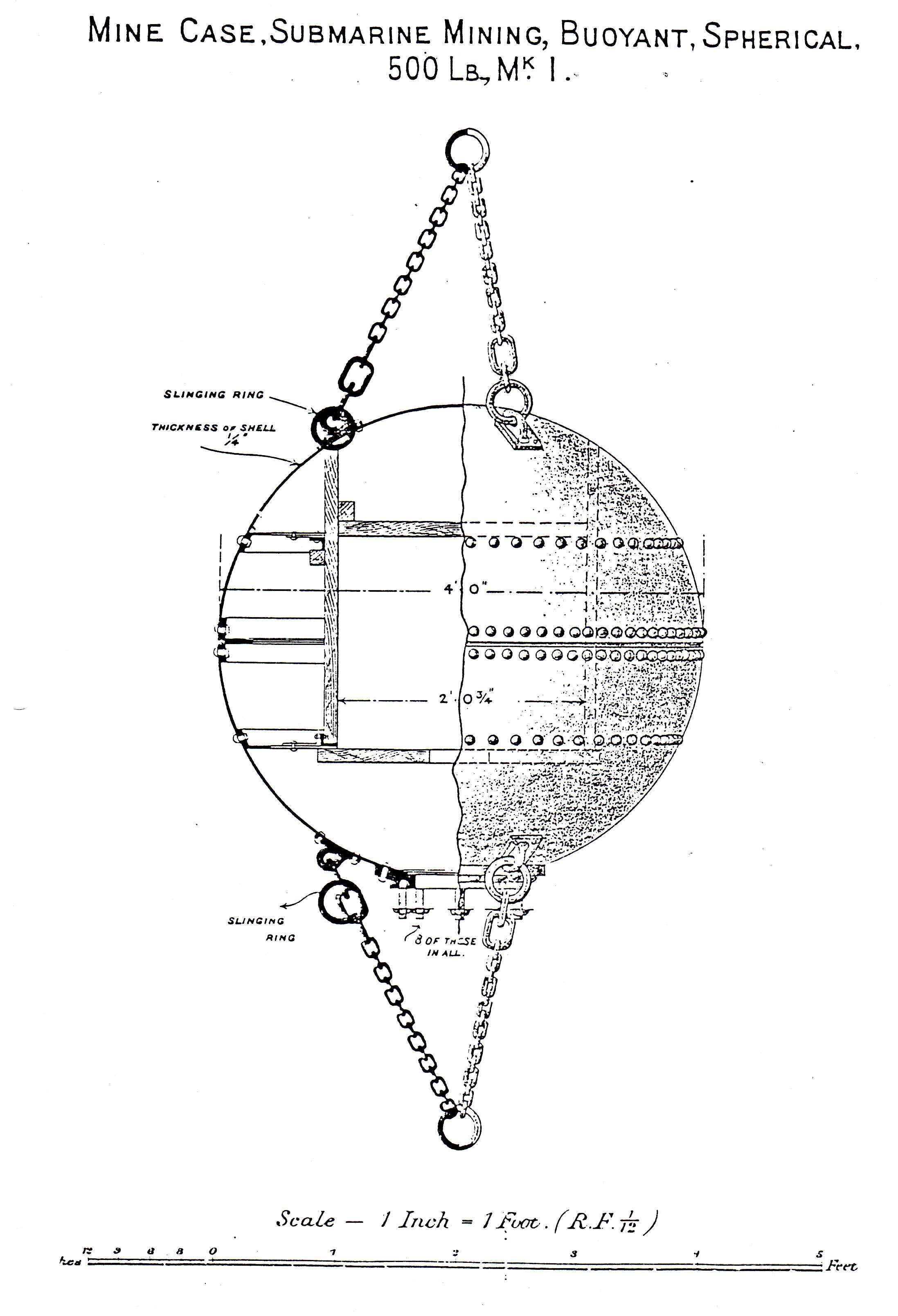

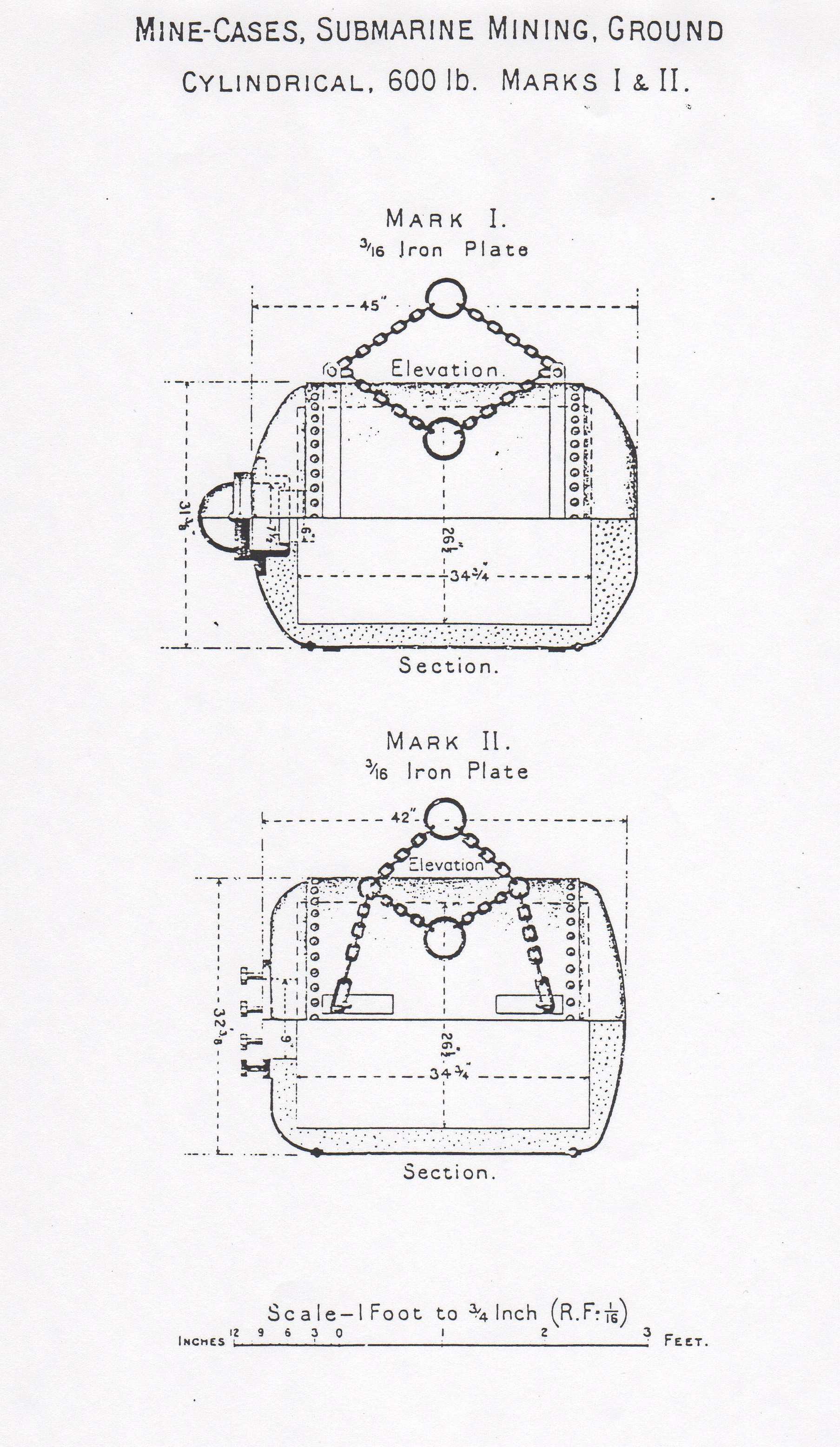

The mine consisted of a charge of gun cotton or dynamite contained in a case and sunk in a river, estuary or channel for the purpose of damaging a hostile ship attempting to pass.

ADDENDUM

NO. 3

SUBMARINE MINING

Until 1870 the term

"torpedo" was used for all explosives charges fired in water, both

what we would call mines and torpedoes. Experiments with such charges had been

going on since the late 18th Century and the Russians had used uncontrolled or

mechanical mines in the Baltic during the Crimean War, but without success. The

first effective use took place during the American Civil War and several nations

thereafter conducted experiments. The Royal Engineers, having exploded charges

underwater against wrecks since the 1830s, took over the mines in British

service, until 1904 when the Royal Navy exerted control after a bitter

inter-Service dispute.

Although originally the

Royal Navy manned the laying vessels, in 1871 the first RE Company was converted

solely to submarine mining, and soon the Royal Engineers had their own growing

fleet of laying vessels. Kipling called the submarine miner "the

Jolly", and said he was "soldier and sailor too". To look at them

– the naval aspect looks more in evidence, but in fact submarine mining work

called both for the brains to understand electrical connecting of mines and the

brawn to hoist them from the laying vessel.

The simplest type

of mine was the mechanical mine which could be detonated in a number of ways:

either collision of mine and vessel would release a pin, which would in turn

release a plunger which was forced into the detonator by a powerful spring; or a

small electric firing battery could be used; or, more crudely, by the mixing of

sulphuric acid, chlorate of potash and sugar. The trouble was that mechanical

mines, once laid and primed, were dangerous to friend and foe alike, and could

close a channel to friendly users.

The answer was the

controlled mine which could be sown inert but connected up via electric cable

to a shore station which could turn it on as soon as war was declared. The

controlled mine was regarded in Britain as the ideal way of defending far-flung

imperial and home merchant ports. The narrowness of the Needles Channel rendered

it ideal for use there, but there was a snag. The strength of the tides meant

that no nines were left sown in peacetime, but were only laid for practice, then

taken up again.

The earliest types of

controlled mine were usually of the "observation" type. In this method

the circuit to tire the mine was closed electrically by two shore-based

observers when a ship's centre bisected the line of sight of both observers.

This was an uncertain method, and in 1885 the Watkin position finder was adapted

for use. One observer in a cell observed the target through the attached

telescope. On its chart were contact studs electrically linked to the

observation mines, which exploded in groups when studs were touched. These

"observation" mines were called "ground mines" because they

could be laid on the sea bed to a depth of 60 feet/18.3 metres, or moored if the

sea bed were further down. To allow for errors in observation 500 lb charges

were used and the cylindrical mines laid in groups of 2 to 4 in up to four lines

so as to "envelop" the ship. Any iron ship within 30 feet of one 500

lb mine would suffer severe hull damage through water-transmitted shock. The

ground mine meant that friendly ships could pass over the minefield in safety.

The drawback was that the system was useless if observers were blinded by fog or

by night, unless searchlights were in constant use.

The answer was the

"electro-contact" or "B.C." mine. After experimentation

with a pear-shaped casing which let in water, the submarine miners settled on a

spherical steel casing. Each mine was moored by chain to a heavy weight or

"sinker" and floated just below the surface. As the mine would fire

only when struck by a ship, it could be used in poor visibility and the charge

could be small, no more than 50 lbs. However, the mine might recoil from the

ship, so a charge -of 100 lbs of gun cotton was normally used. As only one mine

would be exploded, much less cable was used and up to four mines could share one

cable to the shore, each member of the "group" being 150 feet/45.7

metres apart.

When a ship hit the mine

the shock operated a "circuit closer" to complete an electrical

circuit. The mine could be set to explode automatically when this happened, but

suppose the "target" were a friendly vessel? The answer was

the

"retardation" E.C. mine, a type which would also frustrate an enemy

attempt at setting off automatic mines by exploding a countermine underwater.

When struck, the "retardation" mine sent a signal down the cable to a

Test Room ashore. Here it rang a bell in a wall-mounted "shutter box"

screwed to a large batten on a wall, notifying the RE operator even as it

switched on the firing battery. The current tor the cables was provided from

banks of Leclanche cells. After a delay of 4 seconds the operator would

"fire all mines that signal", unless the main firing switch had

already been closed, in which case the mine would explode automatically. Too

long a delay might allow the target to escape. To cancel firing the mine was

"reversed" by sending a weak current of opposite polarity down the

cable to open the circuit closer again.

In 1891 Fort

Victoria became a submarine mining depot. The northern ditch was turned into

tank space in which electric cable was kept in fresh water. The casemates were

turned into stores for loaded or empty mine casings. The best explosive charge

was wet guncotton, set off by a primer of dry guncotton activated by a

detonator.

The mines, after

1883, were stored loaded with the explosive charge. Just before laying a

submarine miner entered a priming pit to fit the primer to the detonator. After

this unit had been inserted into the mine, it would be placed on a truck and

pushed on 18-inch gauge track out to a connecting-up ground where electrical

cable was attached, then taken to a pier and loaded onto a miner for laying.

In the event, the

shore-controlled method (although revived in both World Wars), was largely

replaced about the time of the Russo-Japanese War in 1904 by a less cumbersome

method invented in Germany. The Herz horn gave us the "modern" naval

mine. Each horn was made of lead covering a glass tube containing acid. When the

horn bent on collision and the acid escaped, it ran down on two plates at the

base of the horn - one copper, the other zinc - to form an instantaneous battery

whose current detonated the primer and main charge.

Nevertheless, the

controlled minefield had been good value. A 1903 committee estimated the total

cost of a manned battery of two 9.2-inch guns at £64,000; £40,000 for a

harbour defence submarine; £21,000 for a Brennan torpedo installation; and £30,000

for the mining of a channel 1,000 yards wide.

There was always the danger that an enemy could destroy a minefield, either by "creeping" (cutting electric cables), "sweeping" for the mines with long loops of chain, or "countermining". Hence minefields were to be protected by Q.F. batteries and searchlights. In the Needles Channel the intended minefield off Cliff End was to be covered by three 6-pounder QF installed east of Hurst Castle in 1893, a year after three 3-pounders were emplaced on the roof of Fort Albert.

ADDENDUM NO. 5